BUSINESS

Business Area

Mobile Manufacturing Process

One-stop solution provider

Mold Design & Manufacturing for Smart Phone Assembly → Injecting Raw Materials → High-Speed Injection of Cases → UV Coating

→ EMI (shielding from electromagnetic waves) → Gasket (preventing crosstalk) → Assembly

→ Inspection, followed by released to Samsung Electronics

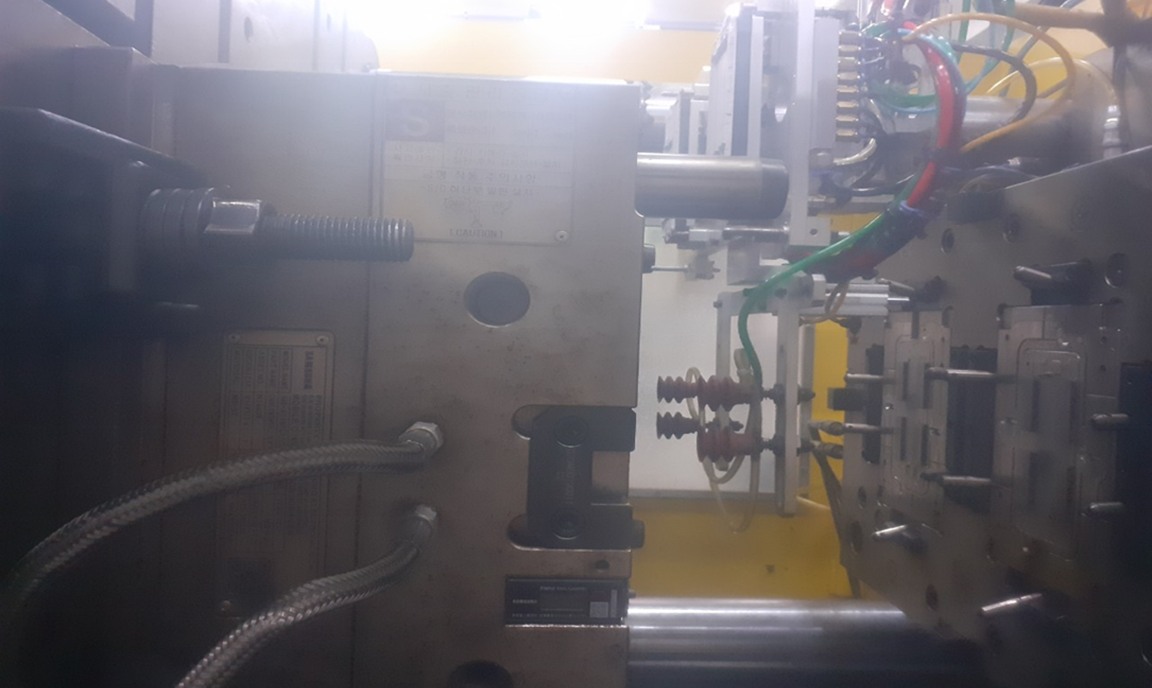

Mold Its own repair system for molds constructed

- A system for immediate repairs when there is any issue in molds or the quality of injection

- Operating the equipment to repair molds

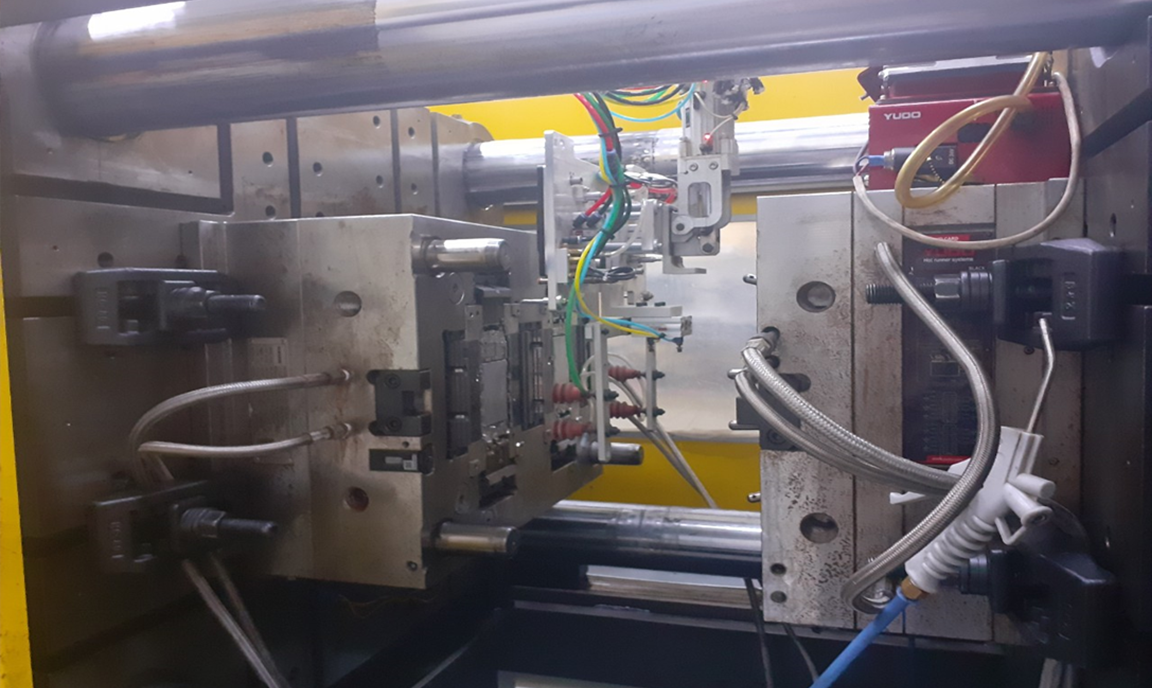

Injection High-speed precise motored injection machine and accessories

- A system of high-speed precise motored injection machine constructed

– improving quality/productivity (Fanuc, Sumitomo) - Auto blowout robot & security camera to protect molds installed

– preventing mold accidents/maximizing work efficiency - Operating molding press individual cooling system (hot water supplier)

& chiller cooling with special specification (4 units) - Operating the automatic mapping system & the center-focused development mapping line

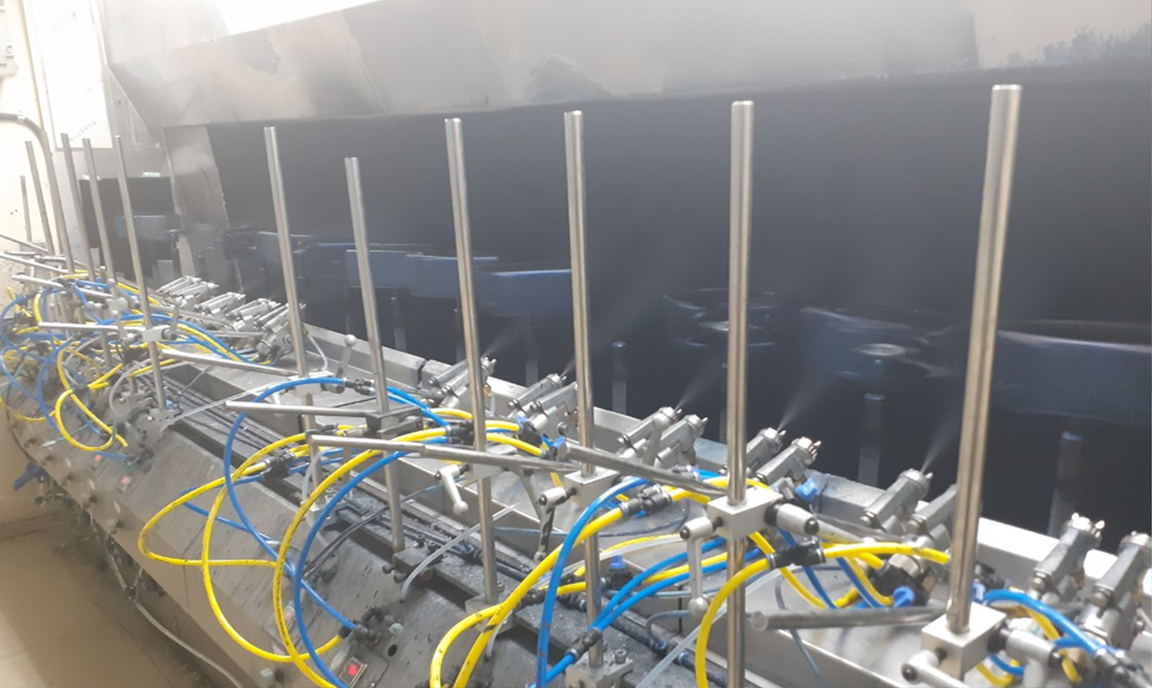

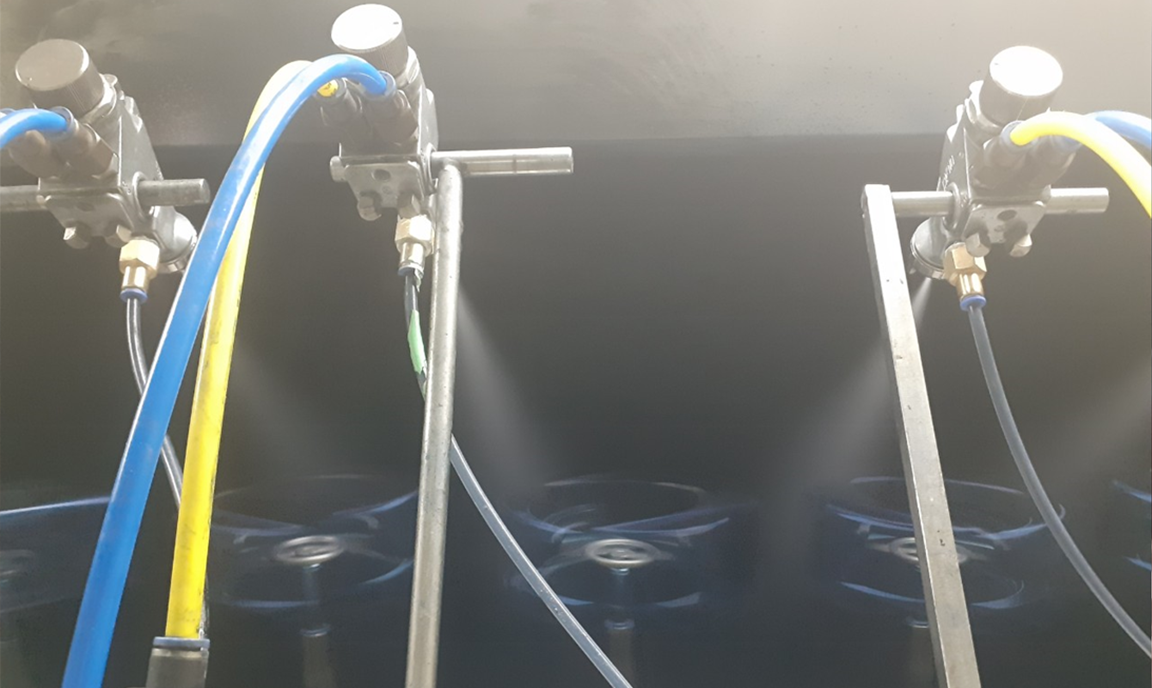

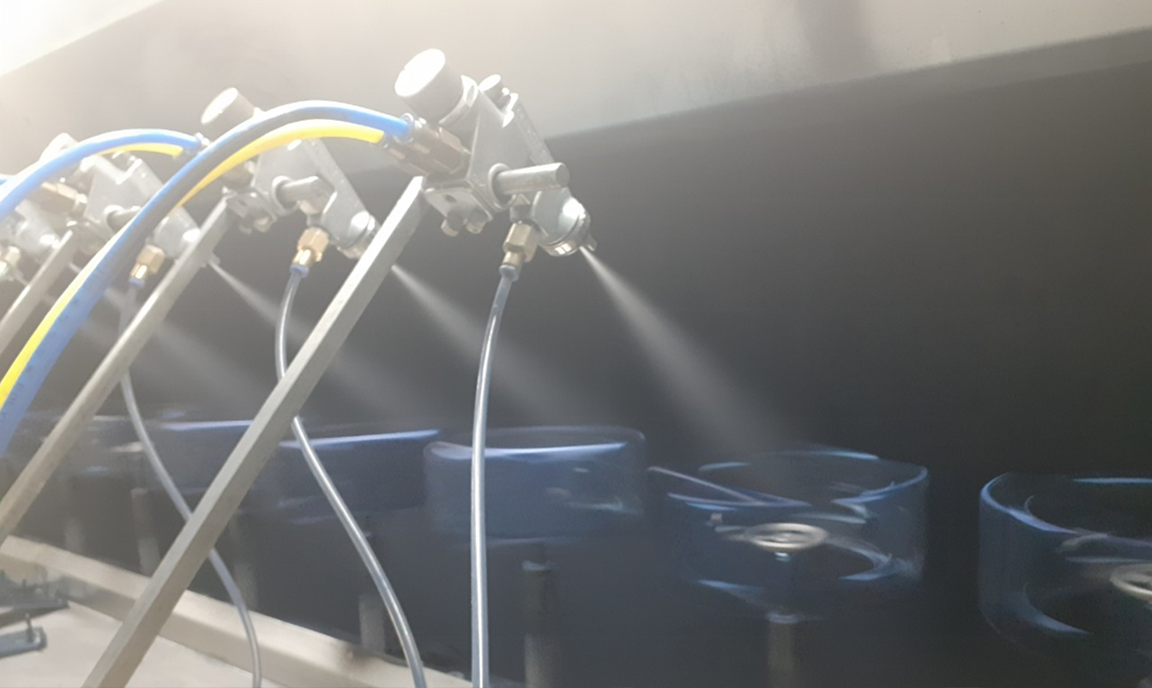

Painting Auto Spray of Painting Process and Printing Equipment

- AUTO-SPRAY SYSTEM & Clean Line – improving quality/productivity

- Spray & External Deposition and Printing /Laser In-House – Quality/Work Efficiency Up

- Selected as an excellent partner for its quality by Samsung & Awarded for its quality

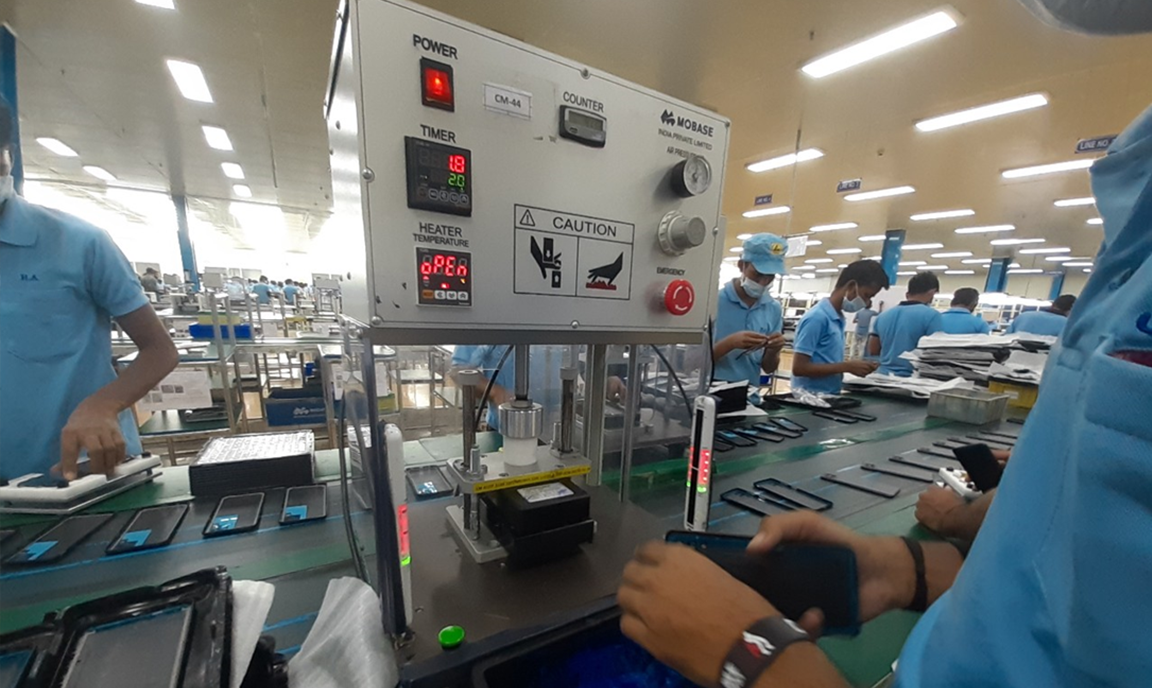

Assembly Automatic Vision Equipment for Assembly Process and Peripheral Equipment

- Operating automatic VISION inspection equipment – securing quality/ productivity

- Wide Follow-up Processes: LASER/NC/Dispensing/Silicon Waterproofing/ UV Curing

– Prepared for High-End Specification

GLOBAL

GLOBAL